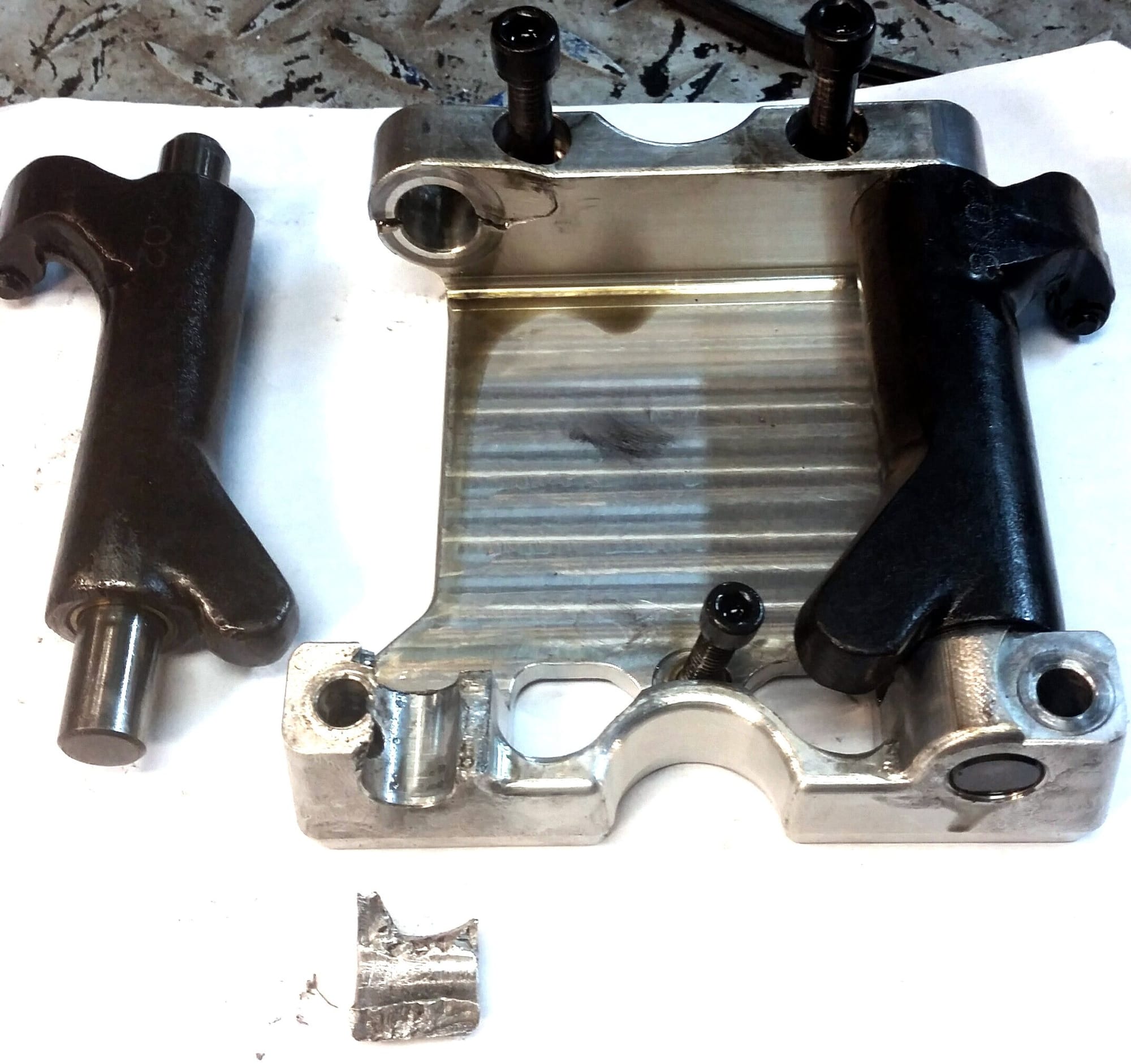

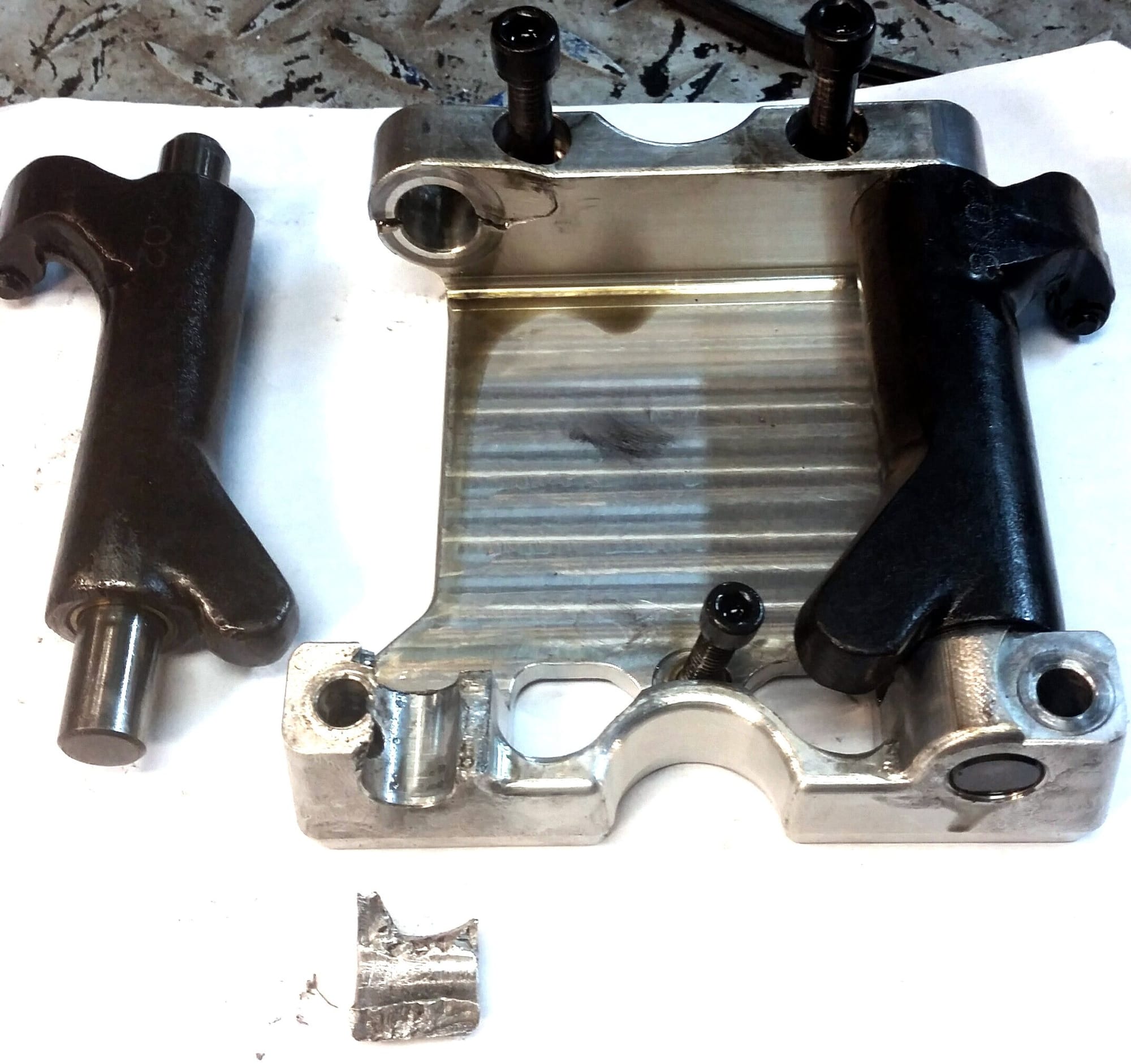

Ive 18000 miles on my 113. Though the tapping/lifter noise has been with this engine for about 15000 miles, not really loud, but noticeable enough to notice. All of which I changed out to Jims lifters and then to Velva touch lifter kit and still Have the lifter tapping noise. Until it got real loud and my engine stopped. When I tore into the engine. Looking under the valve covers for the very first time, since I purchased the engine new in 2009. I found what was the problem. It wasn't the lifters. But the rocker box centers were installed by an idiot at the factory that tightened the rocker center sections down beyond torque specs and also used the wrong sized washers underneath the hex bolts that retain the rocker rods from sliding out and also used washers that were the wrong diameter for the holes they were set in under the socket head bolts.

This is the cause of faulty craftsmanship performed by someone during assembly of my engine at the Ultima Engine plant.

The lifter tapping noise was the rocker hitting the valve cover.

I was very cautious when setting the adjustment on my adjustable pushrods. My adjustment had nothing to do with the metal fatigue/ failure. These parts, even though the engines block has Made in USA stamped on it. The parts that broke and cracked are made in China! The assembly of these parts in the engine was done state side. Built by someone that was a total idiot and didn't give a hoot about their craftsmanship!

Under the socket bolt is a washer ( one that didnt fit) and when the socket head bolt was tightened down. Caused hair line fractures in the aluminum.

Looking at the old washer, one can see that the bolts shoulder, where it attaches to the underside of the bolt head. When tightened down on the washer. The underside of the bolt head made an impression in the washer. Shows that someone over tightened the bolt to cause that impression in the washer.

Looking at this view you can plainly see that the washer used wasn't large enough in diameter.

I made new washers that cover and hold more area like it should have been done in the first place.

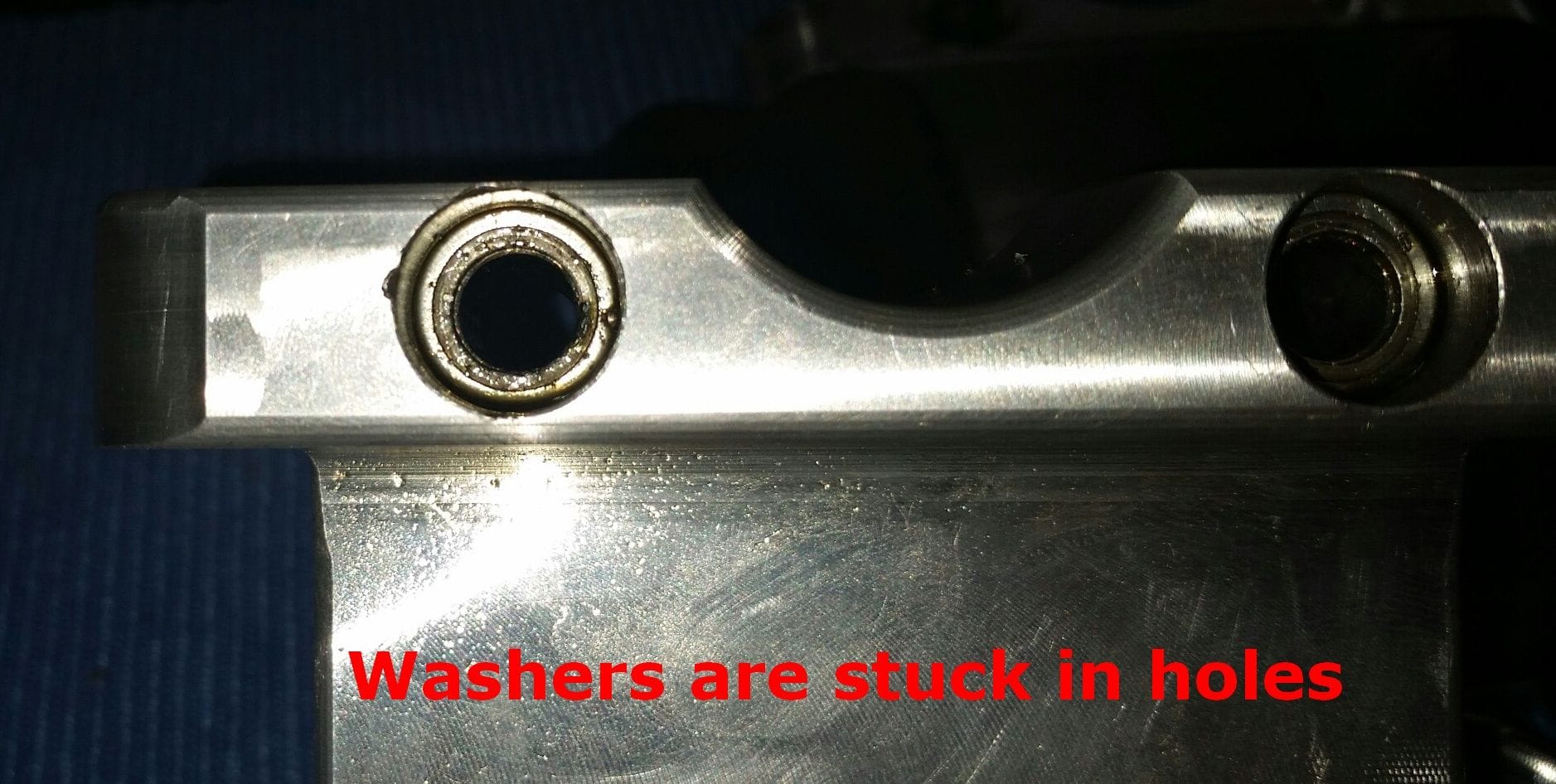

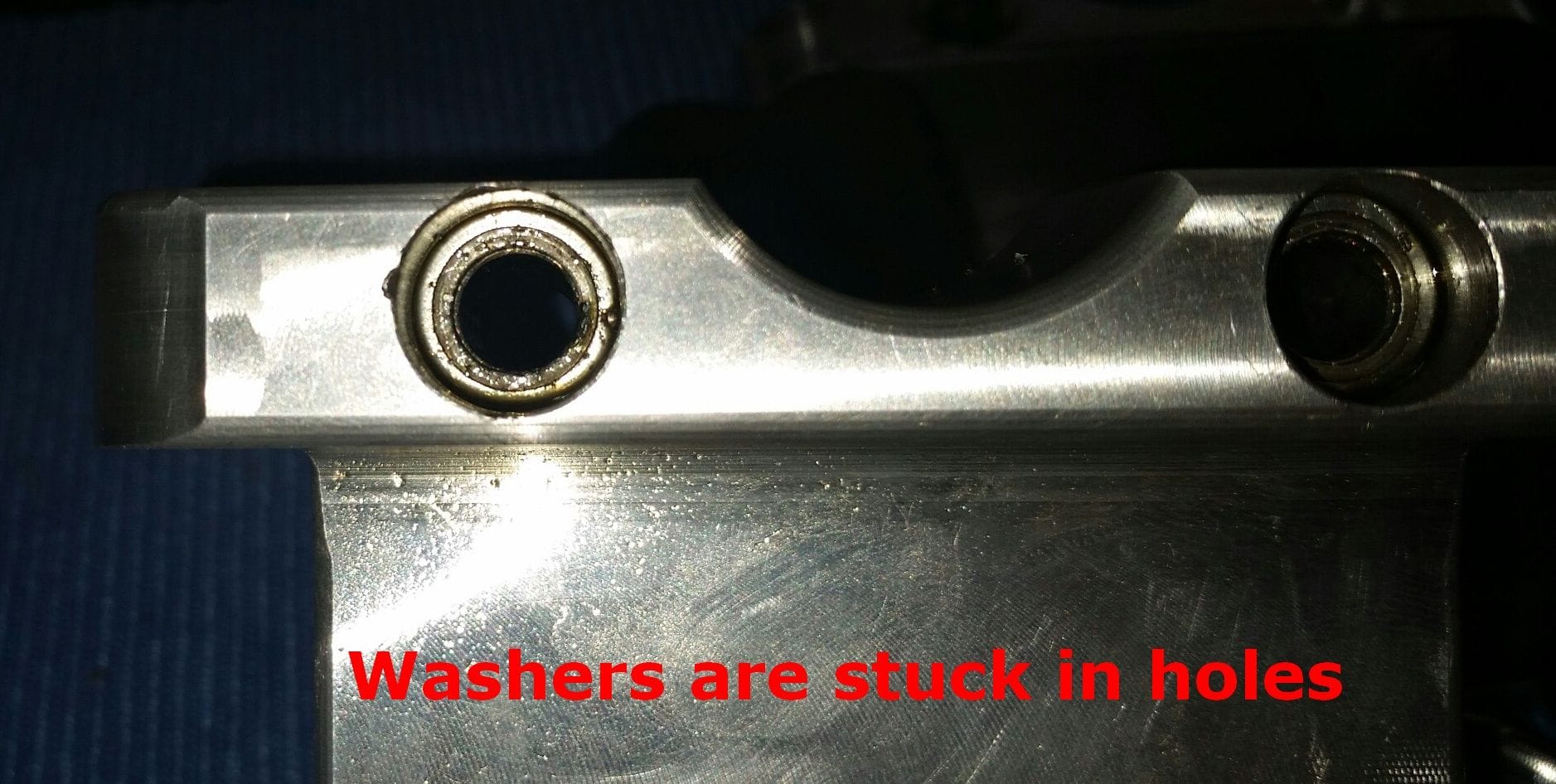

There are washers stuck down in these holes. Though my 1st intentions was to reuse the washers. I found that I couldn't pry them out of the holes!

If any one out there especially with a 113. Please check under your valve covers and look for hairline fractures in the rocker center boxes. I dont believe China is using the aircraft aluminum they are suppose to be using or Ultima isn't inspecting their wares. Either way. I would like to have whomever is seeing these defects in your engine to please post to me in an IM or in here. Ultima says they never seen my problem before. Its up to you ultima owners out there to take a look. its only 12 socket head bolts to remove to look under the valve covers.

zoood/RJ

This is the cause of faulty craftsmanship performed by someone during assembly of my engine at the Ultima Engine plant.

The lifter tapping noise was the rocker hitting the valve cover.

I was very cautious when setting the adjustment on my adjustable pushrods. My adjustment had nothing to do with the metal fatigue/ failure. These parts, even though the engines block has Made in USA stamped on it. The parts that broke and cracked are made in China! The assembly of these parts in the engine was done state side. Built by someone that was a total idiot and didn't give a hoot about their craftsmanship!

Under the socket bolt is a washer ( one that didnt fit) and when the socket head bolt was tightened down. Caused hair line fractures in the aluminum.

Looking at the old washer, one can see that the bolts shoulder, where it attaches to the underside of the bolt head. When tightened down on the washer. The underside of the bolt head made an impression in the washer. Shows that someone over tightened the bolt to cause that impression in the washer.

Looking at this view you can plainly see that the washer used wasn't large enough in diameter.

I made new washers that cover and hold more area like it should have been done in the first place.

There are washers stuck down in these holes. Though my 1st intentions was to reuse the washers. I found that I couldn't pry them out of the holes!

If any one out there especially with a 113. Please check under your valve covers and look for hairline fractures in the rocker center boxes. I dont believe China is using the aircraft aluminum they are suppose to be using or Ultima isn't inspecting their wares. Either way. I would like to have whomever is seeing these defects in your engine to please post to me in an IM or in here. Ultima says they never seen my problem before. Its up to you ultima owners out there to take a look. its only 12 socket head bolts to remove to look under the valve covers.

zoood/RJ