You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

98" Upgrade

- Thread starter dolt

- Start date

dolt

Well-Known Member

Have you been able to do the crank yet?

Hoban Brothers was backlogged big time; just got the crank back last week. Work travel has kept me from completing the build but only the top end is left. The machinist that bored/honed and fitted pistons to cylinders also gapped the rings When I checked the ring gap, I found the rings gapped for a drag race motor that would get the top end replaced after each event; great for power but not so for longevity. This shop has always done my machine work, we just didn't communicate on this one. So I had to order another set of rings from CP; should be in next week and I can finish. We will seat the rings on the dyno and tune; should have something to post soon.

The six speed is new, less than 500 miles; usually takes about 1500 miles or so to "break" them in so I am expecting a minor parasitic loss on power due to the new tranny as well the new parts finding their "sweet" spot and the whole motor loosening up a bit. I will probably get back on the dyno when I have rolled up about 2000 miles on the new motor to get the final numbers.

FYI for anyone installing a DD6 gear set. I was having an intermittent rough 2-3 shift after installing the DD6 and thought I had screwed up the shifter pawl adjustment; rechecked and it was spot on. Called Baker and was told that the shift fork shaft (#30) needed at least .125" of side to side play (don't ask me why) so I checked that and found that I had screwed the set screw (#3) in and the shift fork shaft was pretty tight which I have now corrected. According to Baker, with less than .125" side to side play, the shift fork shaft can bend. I don't know how many of you have had one of those in your hand but I still don't see how it could be bent and am not sure that lacking side play should cause a rough shift limited to the 2-3 shift. But what do I know; Baker's kit so I will defer to the experts. Could just be the parts not quite mated up yet; shall see.

After talking to John at Hoban, I elected not to do the Timken conversion but upgraded both the left and right side crank bearings to the HD "Lefty" bearing. On a bigger motor, say 117" or more, or a drag motor, I would have opted for the Timken conversion.

dolt

Well-Known Member

98" Update for anyone interested.

Got the motor on the dyno last week, 113TQ/112HP. numbers not bad, curve OK but not quite what I wanted; TQ coming in later that what I want. Nick, the tuner, thought the lag was exhaust related; we both blamed the Bassani Pro Streets and thought a 2:1 pipe would bring the TQ in earlier, broaden the curve and maintain the numbers. I had a Python 3 2:1 in storage, pulled it out and put it on, no real improvement on the curve and the numbers dropped a bit. Maybe the Python 3 is just a mediocre pipe so Nick is pulling the D&D Fatcat, the premier 2:1 pipe, off his softail, throw it on and see what happens. I will post a chart comparing the results of the two pipes tomorrow; don't have it on this computer.

I am thinking there is more in this little motor and a different cam set will improve things. So, I have orders a set of Wes Brown's (Cyclerama) new 595 cams. When they arrive, we will run with the different pipes and bottom this exercise out with the best combination.

More to come.

Got the motor on the dyno last week, 113TQ/112HP. numbers not bad, curve OK but not quite what I wanted; TQ coming in later that what I want. Nick, the tuner, thought the lag was exhaust related; we both blamed the Bassani Pro Streets and thought a 2:1 pipe would bring the TQ in earlier, broaden the curve and maintain the numbers. I had a Python 3 2:1 in storage, pulled it out and put it on, no real improvement on the curve and the numbers dropped a bit. Maybe the Python 3 is just a mediocre pipe so Nick is pulling the D&D Fatcat, the premier 2:1 pipe, off his softail, throw it on and see what happens. I will post a chart comparing the results of the two pipes tomorrow; don't have it on this computer.

I am thinking there is more in this little motor and a different cam set will improve things. So, I have orders a set of Wes Brown's (Cyclerama) new 595 cams. When they arrive, we will run with the different pipes and bottom this exercise out with the best combination.

More to come.

Very respectful numbers, i'd be happy with them but if you can squeeze a little more than go for it.

dolt

Well-Known Member

Very respectful numbers, i'd be happy with them but if you can squeeze a little more than go for it.

I know there is more in that motor; just have to get it out.

dolt

Well-Known Member

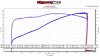

As promised, the chart comparing the Python 3 2:1 with the Bassani Pro Street 2:2 is attached. The Pro Street graph is a completely tuned graph; the Python graph is not. We could have done more pulls with the Python to get a complete tune and the numbers would have improved but not much. The point of the exercise was to see if a 2:1 exhaust would eliminate the front end TQ lag exhibited by the 2:2. As the graph shows the 2:1 curve is sweet, it doesn't bring in the TQ any earlier than the 2:2.

Next exercise will be with another 2:2, a D&D Fatcat; the premier 2:2 pipe, to see if the Python is an average pipe and the D&D is truly a better exhaust.

A set of Cyclerama 595 cams are on the way; different profile but same intake close so static will stay at 10.7:1. We are on the hunt for a better curve and more TQ/HP; fun stuff.

Well, I was going to upload the file but "there was a problem uploading your file". It is a .pdf 303kb; so admin, what's the problem?

Next exercise will be with another 2:2, a D&D Fatcat; the premier 2:2 pipe, to see if the Python is an average pipe and the D&D is truly a better exhaust.

A set of Cyclerama 595 cams are on the way; different profile but same intake close so static will stay at 10.7:1. We are on the hunt for a better curve and more TQ/HP; fun stuff.

Well, I was going to upload the file but "there was a problem uploading your file". It is a .pdf 303kb; so admin, what's the problem?

dolt

Well-Known Member

Haven't gotten around to the Fatcat run yet; pipe will be borrowed so I am at the mercy of the lender but should get it done next week. The Cyclerama 595 cams are in hand; new profile from Wes Brown but we won't try them until we land on an exhaust system. If the D&D pulls the curve left, I will replace the Bassani Pro Streets with a Rush Wraith 2:1.

Red run is Pro Streets 2:2; blue run is Python 3 2:1. Respectable numbers but I would like to see the curve pulled left a bit and 100TQ by 2500rpms. My goal is to do both and increase peak numbers as well.

Red run is Pro Streets 2:2; blue run is Python 3 2:1. Respectable numbers but I would like to see the curve pulled left a bit and 100TQ by 2500rpms. My goal is to do both and increase peak numbers as well.

Attachments

dolt

Well-Known Member

Been a while since I completed the 98" motor and never posted the final dyno sheet; it is attached. The final numbers didn't change much, 115HP/113TQ but the curve is much improved over the previously posted sheet. Final compression bottomed out at 11.2 with CCP just north of 212psi. Don't be afraid of compression guys, it's all in the tune. It's 100* here in south Texas now and not a hint of detonation. The motor hits hard on the street and will pull 6th gear from a 50mph roll on with ease. I don't make a practice of cracking the throttle in 6th gear at 50mph but the motor will pull it without hesitation.

If you are wondering why the almost square numbers and not the usual 10 point variance between TQ and HP, that would be the Cyclerama cams. Wes Brown has figured out how to profile a cam to deliver those results.

Next project for the fall is rebuilding the all bore 107" motor in the '02 FLHT to a 117" motor with a set of worked 110" heads, a set of cams TBD but with .625"-.650" lift and compression somewhere in the 10.8-11.2 range.

If you are wondering why the almost square numbers and not the usual 10 point variance between TQ and HP, that would be the Cyclerama cams. Wes Brown has figured out how to profile a cam to deliver those results.

Next project for the fall is rebuilding the all bore 107" motor in the '02 FLHT to a 117" motor with a set of worked 110" heads, a set of cams TBD but with .625"-.650" lift and compression somewhere in the 10.8-11.2 range.

Attachments

High compression engine, 100 degrees, 50 mph in 6th gear and you crack the throttle with no detonation. Sounds to good to be true. I’d say that’s an unbelievable tune.